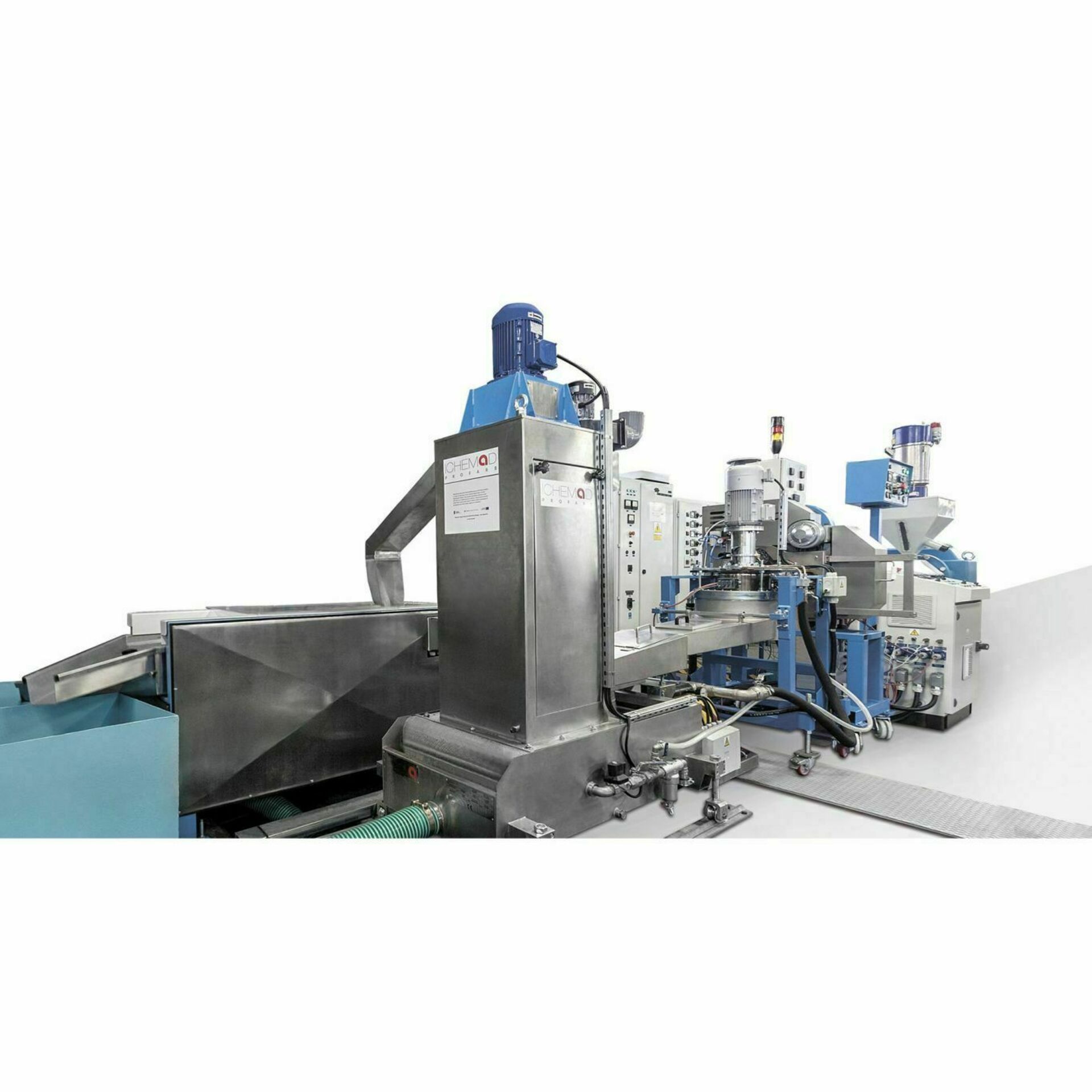

Process lines for granulation and regranulation

Process lines of this kind include the following two basic groups:

- lines with a dual-screw extruder for converting dry blended PVC into granulate or for recycling of prepared, ground PVC waste, using the hot cutting method and air transport and cooling of the granulate,

- lines for regranulation (recycling) of such plastics as PE, PP, PS, ABS, most masterbatches, etc., based on a single-screw extruder, which cut granulate in a water ring and dry it by separating water in centrifuge dryers.

Also, in special cases (e.g. PMMA granulation), ICHEMAD-Profarb can prepare a line for “thread” granulation in which the “threads” coming out of the head are immersion-cooled in a water bath and, once they are dried, they are cut in a granulator with a rotary cutter.

In all plastics recycling cases, the process line is equipped with a plastic filter whose type is selected according to the type of raw material and the specific parameters of the process.

Check the others

Extruders

Complete process lines

ICHEMAD-Profarb sp. z o.o.

Chorzowska 117

44-100 Gliwice

POLSKA

tel. (+48) 32 270 45 41

https://www.linkedin.com/company/ichemad

https://www.linkedin.com/company/ichemad

© ICHEMAD-Profarb sp. z o.o.

made by hands.pl

CMS: